We use cookies to make your experience better. Learn more.

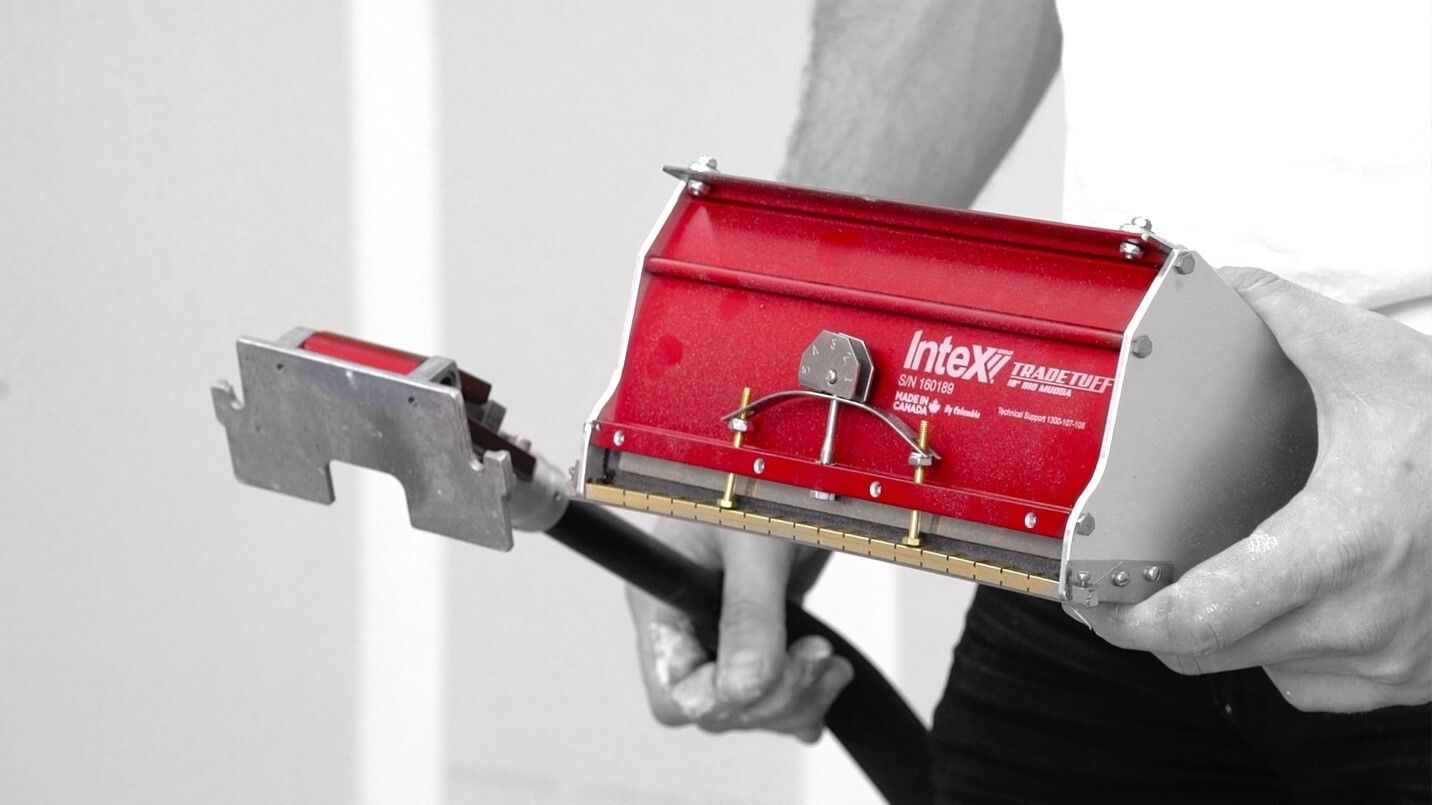

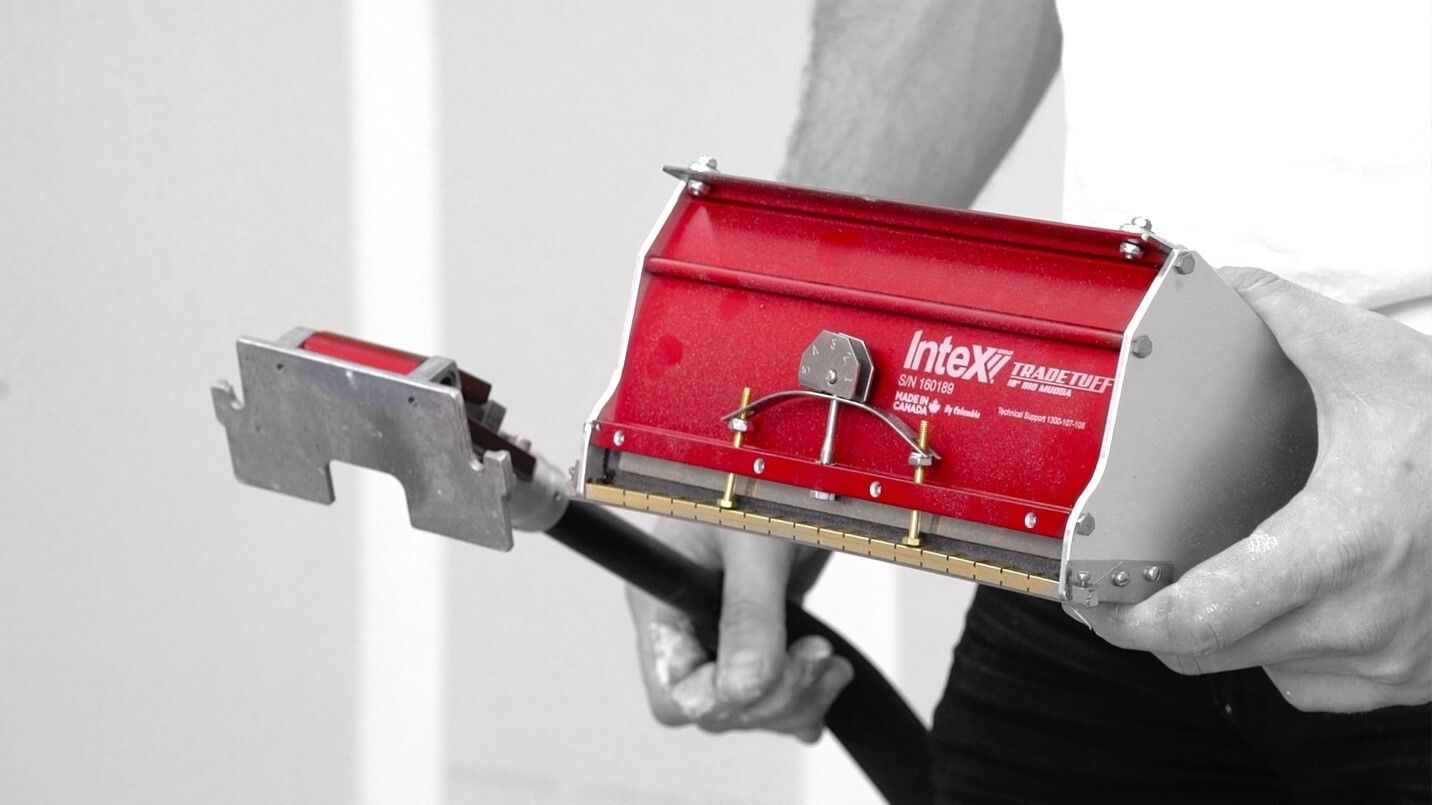

Why Use Automatic Taping and Finishing Tools?

All industry professionals have an opinion about what style of plasterboard tools works best for them. Overall, most agree that hand tools are best for close-quarter finish work, while Automatic Tools are ideal for maximizing production and yielding a more consistent finish.

Most plasterers would agree that a skilled plasterer using his hand-held tools has the “touch”, that special ability to work with the relevant tools, tape, and compound to transform plasterboard fasteners sheets into a monolithic surface that is ready for paint. But let that same skilled plasterer combine his hand finishing skill with the speed and efficiency of Automatic Tools, and the result is a near-flawless product that is produced in much less time.

The use of Automatic Tools speeds the process and accelerates each part of the operation. This takes the fight out of 95% of the taping and finishing process, therefore boosting productivity and yielding a consistent high-quality finish, which in turn helps finish more jobs in a given time frame, generating more profit.

The application method used to achieve the end result makes a substantial impact when timing, job scheduling, resource management, personnel, productivity, and most of all, labour costs are considered. Companies always look for ways to cut costs; a contractor's greatest cost is labour. The question is, how much more board meterage will a plasterer finish each day when using Automatic Taping and Finishing Tools? Research says between 30 - 50%! Others who have made the conversion to Automatic Tools have reported savings of three to five man-days per week/per team.

These are benefits you can expect:

- INCREASED PRODUCTIVITY

- BETTER FINISH

- CONSISTENT RESULTS

- ENHANCES SAFETY

The time savings lies in the ability of the tools to precisely match the rate of compound and tape flow based on the desired speed of the operator. The tools then also control the position of the compound over the joint, evenly distributed and with the proper “crown” through the middle of the joint. This can be a huge productivity gain. If the Automatic Tool is correctly set, seams will require very little finish-sanding.

These tools serve as a quality control system, so that every joint, every inside corner is identical to the next. These Automatic Tools by design create a consistent, high-quality finish however, to master the system and prove the benefits, you must be prepared to learn the skills.

Are you mainly working on small patches or uneven surfaces, or do you finish large new surfaces?

There‘s a suitable tool for any kind of finishing the task. Some come in manual and more automated versions; others can be connected to powered pumps to make the job easier. What’s your forte?

Get the job done quicker:

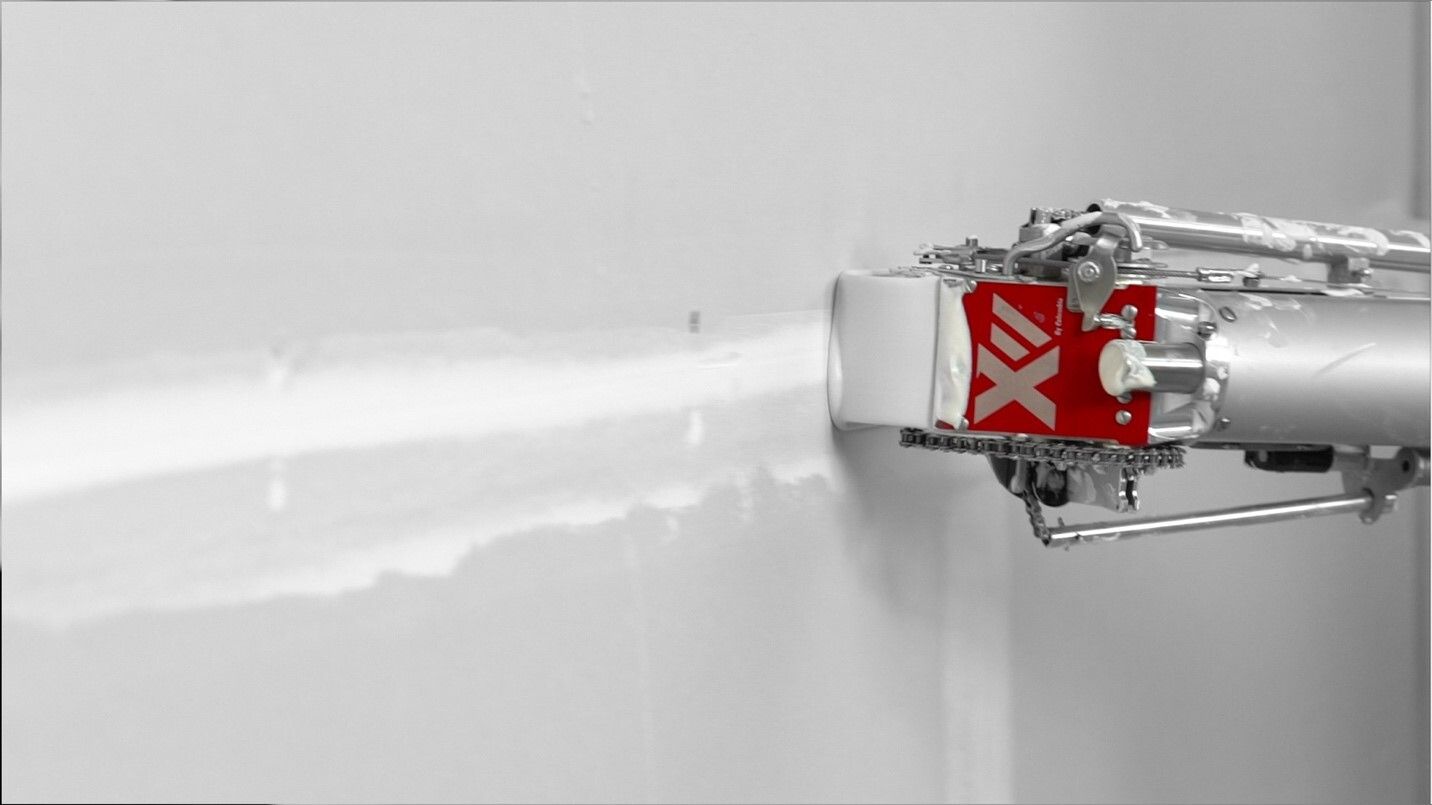

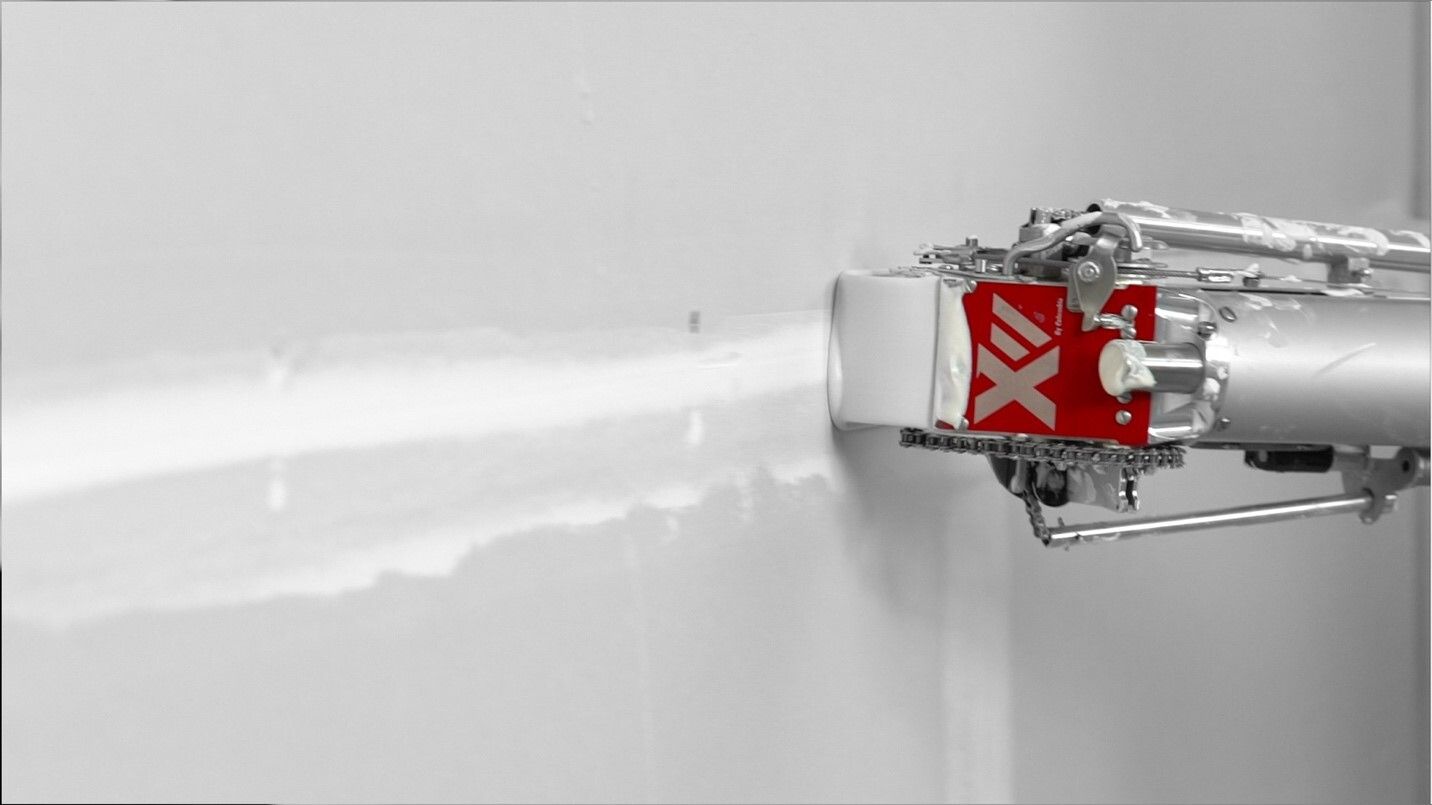

- Continuous Flow Systems are the next level up in ease and speed of work for carrying out finishes up to Q2 level.

- A banjo taper speeds up the manual tape and mud work.

- Drywall flat boxes allow you to work more quickly and easily than with just trowels and knives.

Check out our range of semi-automatic drywall tools here:

Converting from hand methods to a complete Automatic Tool system can be challenging because of the new skills involved. Some professionals who have many years of experience in the industry question their ability to translate a process they have perfected by hand into a new set of tools; however, not surprisingly, experience has shown that the best hand finishers also become the best automatic taping and finishing tool, users!

For more information visit our website, intex.com.au, or contact us directly on 1300 107 108. Don’t forget to follow us on our socials!